-

Weapons for Administration

- Weapons for Administration

- Fabarm Professional

- Daniel Defense

-

Armement / Munitions

- Armement / Munitions

- Armament

- Ammunition

- Reload

- Chargers

- Weapon equipment

- Maintenance - Cleaning

- Targeting

- Security

- Cutlery

- Our packages

- Optics / Optoelectronics

-

Lighting / Signaling

- Lighting / Signaling

- weapon light

- Helmet lamp

- Flashlight

- Headlamp

- Signaling

-

Equipement individuel

- Equipement individuel

- Holsters

- Magazine pouches and accessories

- Girdle / Belt

- Plate holder

- Pockets - Pouches

- Medical

- Protections

- Ballistic

-

Logistics / Transportation

- Logistics / Transportation

- Backpack/Cargo

- Rigid cases

- Textile covers

- Textiles

-

Training / Trainings

- Training / Trainings

- Training weapons and accessories

- Brands

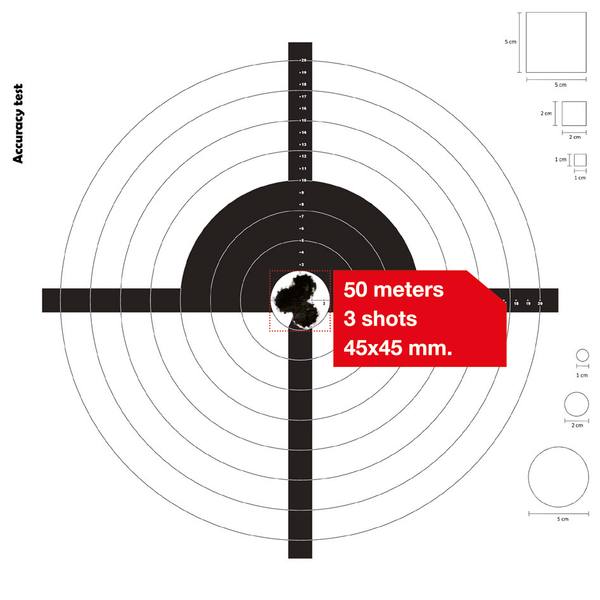

STF/12: AN EXTREMELY PRECISE WEAPON

The STF/12 is to date the rifle offering the best shooting accuracy, as shown by this test carried out at a distance of 50 m with 3 12/70 mm slug impacts in a 45 mm square.

The first reason for such ballistic quality comes from the fact that all STF/12 barrels are produced by out-of-mass drilling of chrome molybdenum steel bars. This technology keeps the molecular structure of the steel intact; the tubes thus remain perfectly straight during the silver welding phase at more than 700°c, unlike those produced by cold hammering.

The second reason has to do with the profile of the barrel itself. The STF/12 have barrels with an increased external diameter to have a better rigidity. The bore of the barrels is also determining: The STF/12 barrels of 11.14 and 18 inches are reamed to 18.4 mm then meticulously polished according to a well determined cycle for more than 6 minutes.

The STF/12 then has an internal choke system, which offers superior accuracy to the cylindrical barrels used by many competitors. An INNER HP ACCURACY type choke, 82 mm long, creates a slight hyperbolic restriction, it was developed to optimize accuracy when firing SLUG cartridges. It allows the use of all CIP standard cartridges

Finally, the "door breacher" muzzle brake also plays a role in this quest for extreme precision at medium and long distances. In addition to the reduction of the recoil which makes it possible to maintain a stable position between shots, this muzzle brake with 3 directions of exit of the propulsion gases greatly reduces turbulence at the rear of the projectile. The trajectory is therefore more linear, more stable and more precise.

- TISAS concession area

- Daniel Defense range

- STF/12: AN UNRIVALED LEVEL OF SECURITY

- STF/12 : THE FLUIDITY OF THE PUMP MECHANISM

- STF/12: AN EXTREMELY PRECISE WEAPON

- THE MODULARITY OF THE STF/12 PLATFORM

- Fabarm Professional range

- Your profile

- Active personnel, security guards & reservists

- Authorities

- Gunsmiths & companies

- export

- Our society

- Catégories des armes

- CHARTE EUROP-ARM / SPORT-ATTITUDE / ARMSCO DE PROTECTION DES DONNÉES PERSONNELLES DANS LE CADRE DE LA RGPD